From idea to mature hardware

Developing a new hardware system is a systematic and structured process. Hawa cooperates closely with specialized partners to create the best sliding solutions. The Hawa Junior 80/B launched in 2015 is such an example. Let’s take a look at product development.

The idea

Hawa continuously develops ideas for new products and product optimization. They are collected systematically and pooled together with market feedback. The art lies in filtering out the idea that will have the best chance on the market. Hawa’s Idea Circle makes use of trend analyses and strategic considerations to decide what will be pursued further and included in the development process. Employees from Research and Development, Marketing and Senior Management are involved in this process.

Market analysis

What Hawa now wants to know: what do partners in the market expect of the new hardware? Hawa is always in close contact with the market during product development and includes its partners in the process right from the start. Cabinet-makers, glazers and metalworkers as well as architects and retailers are surveyed – in structured interviews or via questionnaires. Some are invited to Hawa’s premises to discuss initial product concepts. The requirements distilled from the market analysis flow into the specifications.

Feasibility

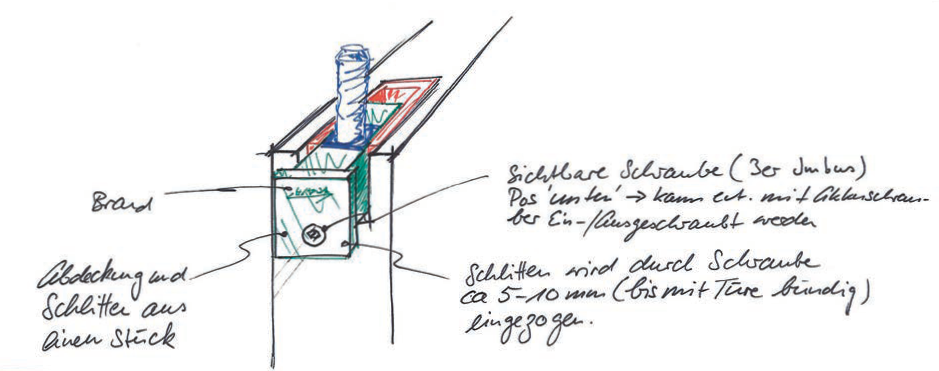

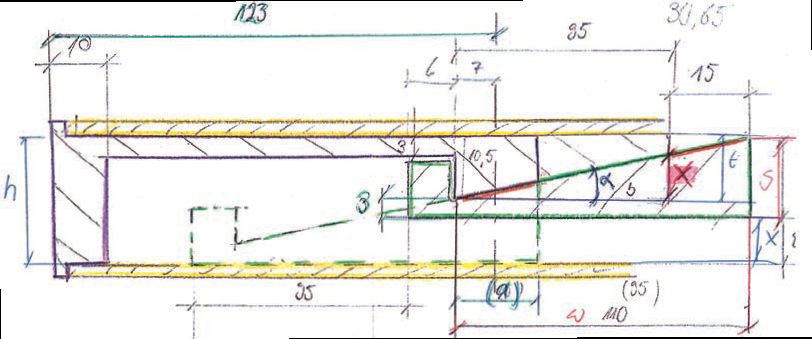

A list of performance specifications is like a big wish list. The crux hereby: many wishes are contradictory. That means not every wish on the list of specifications is grantable. The product manager must therefore set priorities: what requirements are most important to the market and mandatory. Sketches are drawn up that show the product in greater degrees of detail. Deformation and endurance tests are carried out. The project manager in the research and development department minimizes risks and clarifies technical feasibility. The goal is to find the best technically feasible solution for the market.

Planning

Achieving the goal reliably through good planning: the project manager plans the course of development down to the last detail. First, he needs to clarify the interdependencies between the individual steps in the development process: which steps need to be taken first? Which ones can be taken in parallel? Serious planning is essential to ensure compliance with the desired adherence to schedules in the downstream development phases. It includes taking launch dates into consideration, such as trade fairs where the product will be presented.

The concept phase

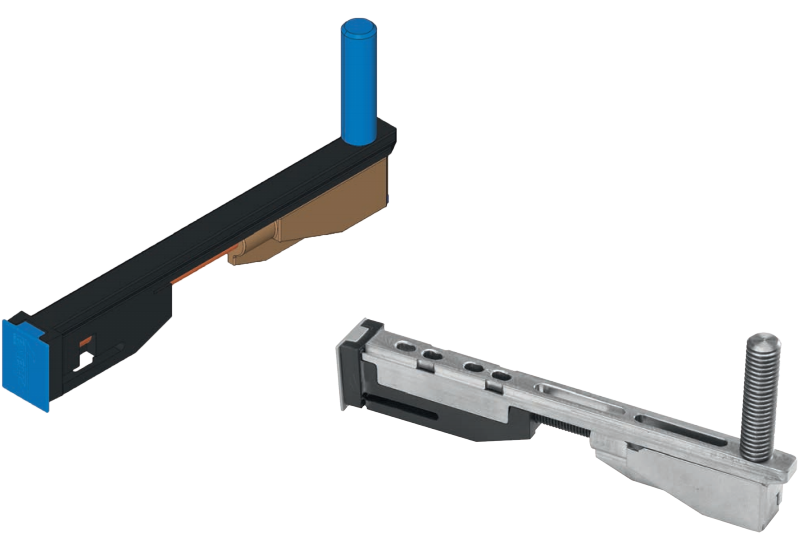

Step by step: Hawa’s developers adopt an iterative approach to the new product. They develop different solution concepts, produce parts on the milling cutter, subject the prototype to endurance tests, discard concepts if necessary, produce them again from scratch and put them to the test once more. The choice of material is a huge challenge as it will guarantee the durability, robustness and safety of Hawa products. High shape accuracy, strong rigidity, high elasticity and fatigue resistance were required in the case of the plastic parts for the Hawa Junior 80/B.

Development

The new hardware system is on the final stretch. All sub-functions of the hardware have been successfully designed and verified. Once it is clear that the hardware works in principle, it needs to put its practical suitability to the test. During design validation, a milestone in product development, external specialist partners such as cabinet-makers and metalworkers work together with Hawa employees to test the new hardware on a model. They fit a functional sample from A to Z and check the installation process, running properties, etc., as well as the accuracy of planning and assembly instructions.

Final adjustments for serial production

The hardware has passed every test and continues development to a serial product. The corresponding tools are ordered and production begins. The first parts produced in series – the so-called zero series – are used to carry out all of the tests once again. This is the only way to guarantee Hawa’s high demands on quality.